Tank truck refers to the special oil transportation vehicle equipped with a tank container, which is mainly used for transportation and storage of liquid chemicals such as gasoline, diesel oil, crude oil, lubricating oil, coal tar and edible oil. The gear oil pump can be installed on the vehicle, and the pumping and pumping functions can be realized by taking the power of the main vehicle engine, and various oil dispensing and discharging functions can be realized after the binning. The fuel truck consists of a power take-off, a drive shaft, a gear oil pump, a tank body, and a pipe network system. The pipe network system consists of oil pump, three-way four-position ball valve, two-way ball valve, filter screen and pipeline. In addition, the fuel truck can be equipped with a vehicle-mounted tanker, which can be used to measure fuel by liter or by amount, and optional flow meter with fuel. The reel and the refueling gun became the mobile refueling truck - "mobile gas station".

According to the user's requirements, the fuel truck can be equipped with a gear pump, a centrifugal pump, a heavy oil pump and a stainless steel pump. It can be equipped with a heating pipe and an insulation layer. The tank has semi-circular cans and square cans.

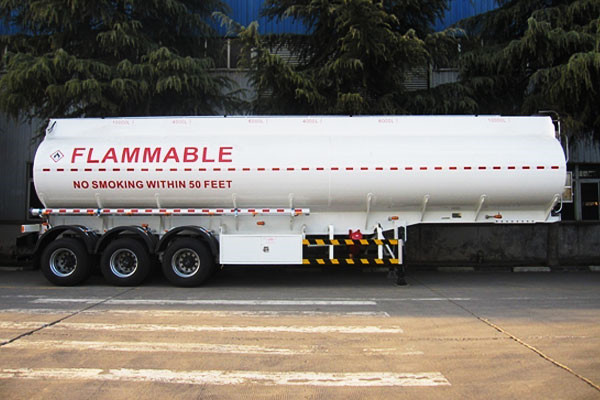

Tank truck is divided into small tank trucks, medium tank trucks, large tank trucks, and semi-trailed Tank trucks.

Tank truck is divided into Dongfeng Tank truck liberation Tank truck according to the type of chassis. Foto truck Futian Auman Tank truck Fukuda era Tank truck Fukuda Aoyun Tank truck Jiangling Tank truck Jianghua Tank truck Shaanxi truck Tank truck Heavy truck Tank truck.

1 The chassis is different, the price is different: because the brand and configuration of the car chassis are different, the price is different;

2 Different accessories, different prices: because of the different use of auto parts, the price difference;

3 Different materials, different prices: the type of material used in the tank, and the amount of materials used, so that the price is different;

1. The tank body is made of 4mm or 5mm high-quality carbon steel plate, which is manufactured according to the national Tank truck production standard and butt welding process. The shape is divided into oval or square cans.

2. There are multiple anti-wave separators in the tank. The high-pressure gas leak detection is used to make the tank have high strength, stable center of gravity, and safe and stable vehicle transportation.

3. All kinds of alcohol, sulfuric acid, hydrochloric acid and salt liquid chemical tankers are made of stainless steel imported from South Korea (thickness is 4mm-5mm) or plastic can (polypropylene) (thickness is 12mm-22mm).

Precautions when driving a Tank truck

First of all, the big station requires that the oil-laden vehicle and the driver must hold the dangerous goods transport certificate and the flammable and explosive training certificate, and only the Tank truck driver and the oil loader enter the loading area. The entry vehicle must have a fire-proof cap. Weaving a pit stop network;

Secondly, the light oil loading management regulations have been re-improved, and the pre-loading preparations and the precautions for loading are strictly and meticulously stipulated. Everyone masters, thus weaving a network of operational specifications.

In addition, for the maintenance of the flammable and explosive tank, the tank should be washed first. After flushing, it is best to use steam to completely evaporate the gasoline inside the tank and then weld it to prevent explosion. The occurrence of an accident;

According to its position in the ignition system, it can be divided into two cases: Tank truck low voltage circuit failure and high voltage circuit failure.

(1)Tank truck low voltage circuit common faults:

Insufficient battery storage; poor connection or disorder of the cable; poor battery grounding; damage to the distributor or Hall sensor; damage to the ignition switch or poor wiring; damage to the transistor ignition control unit or poor wiring. Most of Tank truck's low-voltage circuit fault diagnosis methods use an ammeter or voltmeter line-by-line check to eliminate the fault point.

(2) Common faults in Tank truck high voltage circuits:

Tank truck high-voltage line off or leakage; distributor cap rupture breakdown; distributor splitter ablation burst breakdown; spark plug electrode gap is too large or too small; spark plug excess carbon; spark plug insulator damage; ignition coil damage or wiring off. Most of the faults of high-voltage circuits use high-voltage test fire method. The high-voltage line of the distributor center or the high-voltage line of a certain cylinder is unplugged. The line head is placed 3-6mm away from the cylinder, and the engine is fired. There is spark and the spark is strong, indicating that the ignition system is working normally. .

(1) Fault phenomenon: Turn on the ignition switch, start the engine, the engine has no reaction; high-pressure test fire, the high-voltage line has no spark.

(2) Failure analysis and diagnosis

3.Tank truck ignition time is too early

(1) Fault phenomenon: The idle speed is not stable and the flame is easy to extinguish; when accelerating, the engine has a serious detonation sound.

(2) Fault analysis: The fault is mainly caused by misalignment of the ignition timing or misalignment of the ignition angle.

(3) Exclusion method: Connect the ignition tester and adjust the ignition advance angle to the specified value.

(1) Fault phenomenon: The sound of the silencer is heavy, the carburetor is tempered, the engine coolant temperature is high, and the car is running weak.

(2) Failure analysis and diagnosis: The ignition angle is not correct.

(3) Remedy: Adjust the ignition angle to the specified value.

The main faults are: spark plug carbon deposit, oil stain and overheating

The spark plug is overheated: the center electrode is melted, the top of the insulator is loose and soft, and the insulator end is mostly grayish white.

Spark plug carbon deposits: The insulator ends, electrodes and spark plug shells are often covered with a layer of relatively thick black-gray powdery soft deposits.

Spark plug oil: Fault phenomenon: The insulator end, the electrode and the spark plug shell are covered with a layer of oil.

The Tank truck engine is most prone to knocking at high loads and medium speeds. In the case where the fuel grade is correct, the knocking phenomenon is mostly caused by the excessive ignition advance angle. In the event of a knock, the engine heats up quickly. On the other hand, the ignition advance angle is too backward, the ignition is too late, and the Tank truck engine temperature is also high. In the absence of knocking, most of the water temperature is not caused by the ignition system, but if the engine is weak and the acceleration is not sensitive, it should be checked whether the ignition advance angle is too small.

The Tank truck fire includes the railway Tank truck and the car Tank truck. Tank truck manhole fires often occur due to ignition of iron, such as iron collisions, static electricity, and lightning. Tank truck people's orifice fires generally form stable combustion, the flame is torch-like, and the flame temperature is high, which is a great threat to the loading and unloading crane pipe, the trestle bridge and the Tank truck itself.

1. Isolation fire fighting method. Isolation fire extinguishing can be extinguished by means of water flow closure, water spray, covering, etc., in which the asbestos is used to cover the tank mouth, or the Tank truck manhole cover is closed, so that the oil and gas are isolated from the air and the flame is extinguished more conveniently and effectively.

2. Use a fire extinguisher to extinguish the fire. Most of the loading and unloading operations are equipped with dry powder fire extinguishers, which can be used to spray holes in the manhole to extinguish the flame. This kind of fire extinguishing method works best at the beginning of the fire.

3. DC water gun to extinguish the fire. When the fire is long and the flame is large and the firefighters cannot access it, it is advisable to use several DC water guns to form a water curtain to prevent the air from extinguishing the fire. It is also possible to use a foam hook pipe to hang the foam in the tank hole to fire the foam into the tank.

4. Precautions

In the event of a fire in the Tank truck, the emergency valve should normally be closed, the loading and unloading operations should be stopped, the oil source should be shut off, and the loading and unloading crane pipe should be removed from the Tank truck. Generally, the unburned Tank truck should be evacuated to a safe area, and the surrounding combustibles should be evacuated according to the specific circumstances. The fire tank can also be evacuated to a safe place to extinguish the fire if conditions permit. After a fire in Tank Truck, cooling measures should be taken as early as possible to protect the Tank truck, crane, bridge and surrounding buildings to prevent fires from expanding.

Address:Zhangheng Street corner Guanlin Road, Science and Technology Park, Luolong District, Luoyang City, Henan Province

E-mail:shiyk@lingyu.com

Phone:0086-379-65937678