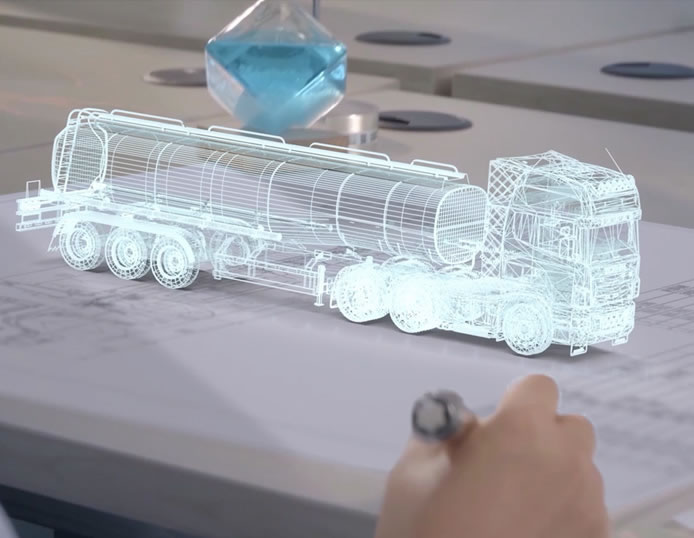

A cement bulk carrier is a type of ship designed specifically for the transportation of bulk cargoes, such as cement. These ships are equipped with large storage areas and specialized equipment for loading and unloading the heavy, powdery cargo. The storage areas on a cement bulk carrier are typically enclosed to prevent the loss of product during transit, and the ship's design allows for efficient and safe handling of the material. Cement bulk carriers are usually larger than other types of bulk carriers and have a greater deadweight tonnage to accommodate the heavy cargo. These ships play a critical role in the transportation of cement from production facilities to market, ensuring the timely delivery of a crucial material for construction and infrastructure projects.

CIMC cement bulk carrier and powder material tanker semi trailer are widely used for transporting and storing cement, coal powder, dry mortar, food and chemical powder. The vehicle can effectively improve transport efficiency, reduce transport cost, decrease pollution, and meanwhile, realize the mechanization of loading, transporting, discharging and storage.

CIMC has the most advanced and most professional cement bulk carrier assembly line, guaranteed all products have unique and attractive appearance. All structural parts have been treated with shot blast pre-treated technology.Tank parts are welded with special tank clamp equipment and panasonic automatic welder. The coating and painting adopt high quality bus baking varnish standard, the topcoats life is generally 2-3 times longer than other manufacturers. The cement bulk carrier is designed and covered the most nationalheavy duty truck chassis and leading imported chassis. Including more than 60 filing vehicle models achieved most complete in industry.

Semi Trailer Series Cement Bulk Carrier

FAW Series Cement Bulk Carrier

Shacman Series Cement Bulk Carrier

Sinotruk Series Cement Bulk Carrier

Auman Series Cement Bulk Carrier

Dongfeng Series Cement Bulk Carrier

01

Best Raw Materials

01

Best Raw Materials

Tank steel plates Q235, Q345, Q550, AG610L, AG700MC, etc., use high-strength steel plates of well-known domestic steel mills, tensile strength of more than 620Mpa, good mechanical properties, reliable welding, high strength and light weight.

02

Lightest Weight

02

Lightest Weight

The cement bulk carrier body is made of high-quality low-alloy high-strength steel plate, and the vehicle body has been optimized in all aspects, which makes the top-loading part reduce 600-800KG, surpassing all the similar products in the market and reaching the lightest in the industry; the high-strength steel cement bulk carrier body is greatly reduced; for different road conditions, Different optimized design of the frame to minimize the weight; using ultra-light and high-performance air suspension, high-quality self-weight axle, the lightest vehicle industry.

03

Fastest Unloading

03

Fastest Unloading

Through the bold upgrade of related structural components such as fluidization angle and repose angle, the balance point is re-determined between the tank volume, quality and discharge speed according to market demand, and the unloading speed is greatly improved, and the industry is the fastest.

04

Humanized Design

04

Humanized Design

The cement bulk carrier bypasses the intake line from the front head to the left side, solving the problem of interference with the chassis drive shaft. The dry-mix mortar transporter transfers the piping system to the side of the air compressor to completely solve the pipeline problem.

05

Dual Power Solutions

05

Dual Power Solutions

According to the requirements of different users, the dual-power scheme can be selected, and the motor can be used to drive the air compressor to reduce fuel consumption, effectively reduce costs and improve operational efficiency. (Patent No.: ZL 200820069839.0)

06

Tank-cap of Patent Technology

05

Tank-cap of Patent Technology

Obtained the national patent, domestic independent – no. The can lid adopts a centrally compressed screwing method, which has good sealing performance, flexible and light operation, and is safe and reliable.

07

Reinforced Sub-frame

07

Reinforced Sub-frame

The underframe longitudinal beam adopts the original closed structure, which is closely attached to the tank body, with higher strength and better carrying capacity. The side of the joint between the tank body and the auxiliary beam is increased side support to enhance the joint strength and prevent the splitting of the auxiliary beam to make the operation safer.

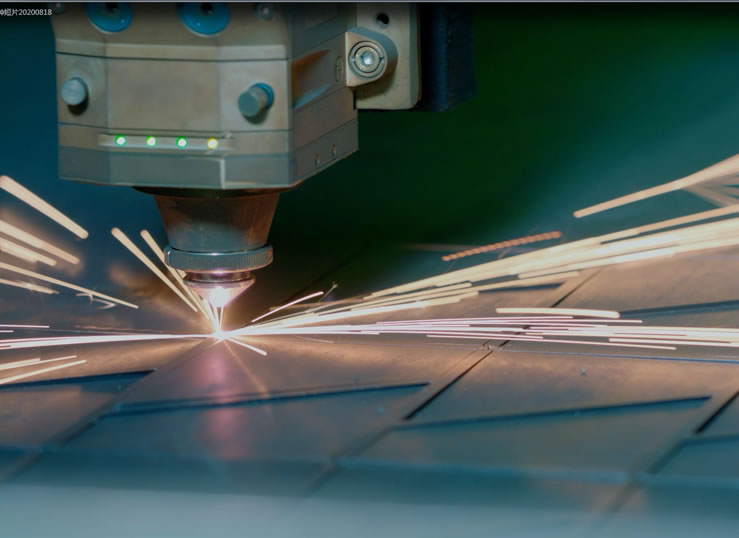

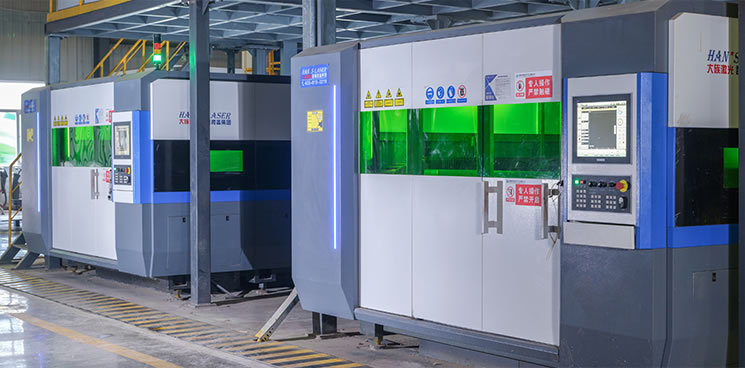

Blanking process

All tank body, accessories, and inner material are processed with large scale numerical control plasma cutting machine, numerical control punch and other special equipments, the equipment brings less errors and high precision , ensure the product geometric accuracy and increase production efficiency as well.

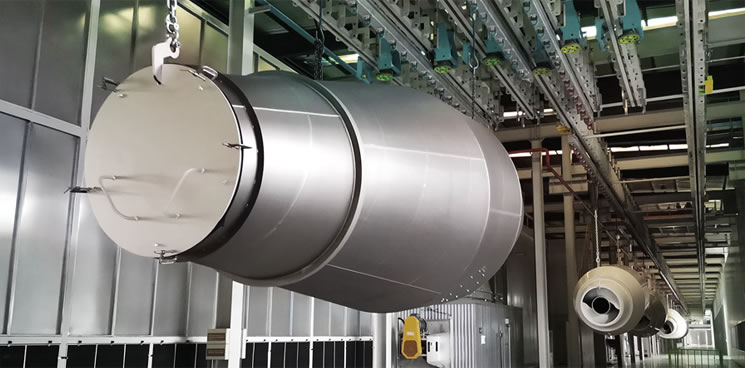

Welding process

CIMC Group holds the leading welding quality in national same industry. The tank is shaped with special hydraulic roller and tank body is welded with automatic joint machine, with single-side welding, double-side shaping process. The tank body was rolled by a 10 meter one-step round roller. The unique advanced spot welding tooling, wheel frame support transport operators and gith welding tooling will ensure tank intensity, quality and appearance.

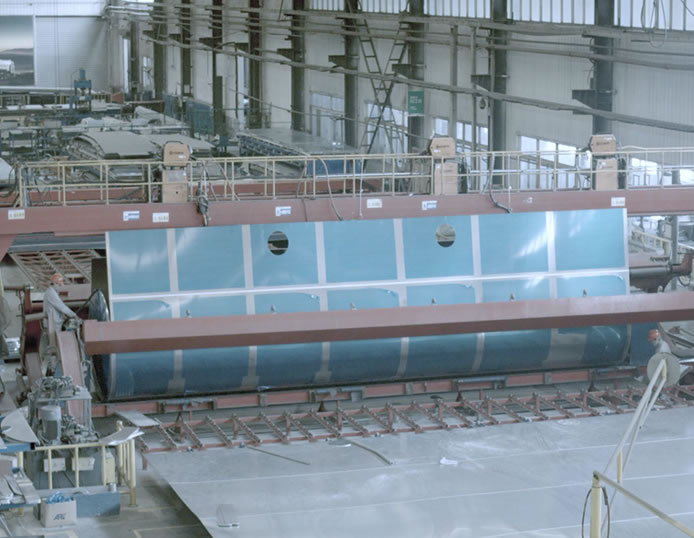

Painting process

Tank body and spare parts are pre-treated with shot blasting in order to remove the rust and eliminate oil. Further it can improve surface intensity and painting adhesion, lay a sound foundation for painting. Painting adopts luxury bus coating process and use dust- -free spray paint and baking process both finish paint and anti- -rusting capability are the first class in the same industry. (CIMC LINYU is the only factory which use the coach coating process for engineering vehicles quantity.

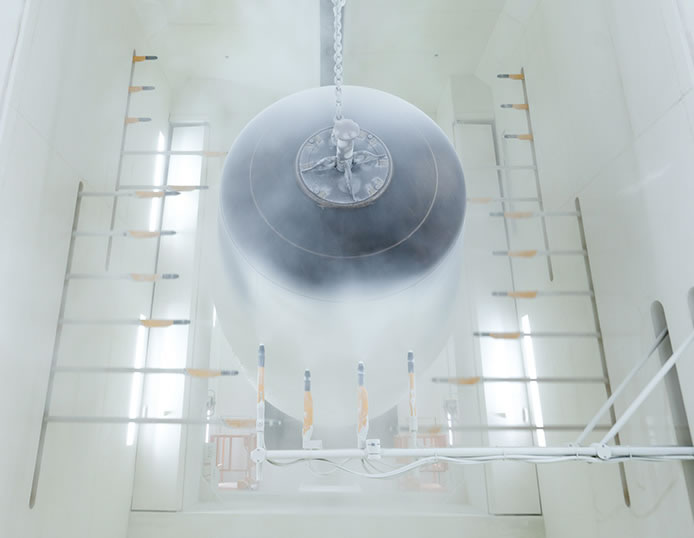

Assembly process

Rational assembly process layout, strict quality control system, guaran-tees excellent production and increased production ability. Guaranteed the vehicle stable and reliable quality.

Inspection and test process

After adjustment and test, all vehicle products will be conducted with compulsory inspection on front wheel sideslip, lamps, brake system and other items on the automatic inspection line, to ensure reliability and safety.

2023-02-28

2023-02-28

What are the roles of cement bulk carriers in the construction industry

A cement bulk carrier, also known as a cement tanker, is a type of truck or trailer used for tran...

2022-09-14

2022-09-14

What are the functions of the fluidization device installed on the cement bulk carrier?

The cement bulk carrier is mainly used for the bulk transportation of fly ash, cement, lime powde...

![[2022 "Super Tiger Imagination"] Linyu's new cement bulk carrier is here for you! [2022 "Super Tiger Imagination"] Linyu's new cement bulk carrier is here for you!](https://www.ly-cimc-linyu.com/media/news_images/low-density_cement_bulk_carrier.png) 2022-06-06

2022-06-06

[2022 "Super Tiger Imagination"] Linyu's new cement bulk carrier is here for you!

CIMC Linyu has always strictly adhered to the customer-oriented service concept, and continuously...

2022-06-06

2022-06-06

In-depth analysis of the success secret of Linyu cement bulk carrier

With the full recovery of the economy, all walks of life are gradually on the right track. As the...

2022-06-06

2022-06-06

To play "color wear and match" this winter, Linyu's colorful cement bulk carrier set off for **

Entering December, the cold weather could not resist the enthusiasm of Linyu people. All the staf...

2022-06-06

2022-06-06

There are doubts about smashing "cans" and win the trend of the times

Lightweight and compliant, excellent to impeccable, many tank truck drivers have various doubts a...