In the concrete transportation industry, time is profit, and uptime is lifeline.

Every loading, hauling, and unloading operation is a battle against time, temperature, and road conditions. They face unexpected order surges, complex and ever-changing construction site environments, increasingly stringent emission standards, and spiraling fuel prices and operating costs. In this competitive landscape, simply being able to "run" is no longer enough; the real key lies in whose truck is the most economical, most stable, and most profitable.

Ⅰ. The Real Pain Point: It's Not That the Truck is Expensive, It's That the Truck Is "Unprofitable"

After two or three years of use, traditional concrete mixer trucks experience increased fuel consumption, tank wear, and frequent chassis failures. Not only are maintenance costs high, but the most worrying aspect is that when customers push for orders or project deadlines approach, the trucks become idle, driving up costs. Every unplanned downtime represents lost profits; every delay in repairs represents a decline in reputation. Concrete transportation companies know firsthand that reliability is more sensitive than price, and that on-site performance is more important than factory data. A good truck doesn't win by low prices, but by long-term profitability.

II. When "Smart Manufacturing" Meets "Hardcore Power"

CIMC Vehicles & FAW Jiefang's new energy concrete mixer trucks are more than a simple combination. CIMC Vehicles, a global technology leader in the special-purpose vehicle industry, has over a decade of experience in concrete mixer truck manufacturing. From concrete mixer tank geometry design and material selection to intelligent manufacturing processes, they continuously optimize vehicle lightweighting and durability. FAW Jiefang, a mainstay of China's heavy-duty truck industry, offers a robust powertrain, a mature chassis platform, and a nationwide service network, making it the most reliable foundation for concrete mixer trucks. The combination of these two makes concrete mixer trucks more than just a "tool," but a highly efficient and profitable system.

Ⅲ. Electric Drive × Intelligent Control × Lightweight Structure

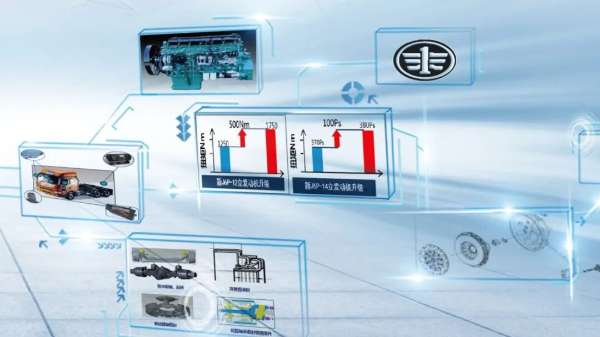

▐ More Powerful

A dedicated power chain for concrete mixer trucks and a low-speed, high-torque engine deliver even more power. A rational speed ratio, low-friction sub-transmission, and rear axle ensure smooth gear shifting.

A low-drag cab and intake and exhaust ensure optimal vehicle economy and superior power compared to similar products, making it suitable for a variety of complex construction site conditions.

▐ Lighter

Using topology optimization and discrete element technology for a lightweight design, the product is over 10% lighter than the industry average.

Lightweight materials are used, including an all-aluminum transmission (China VI new J6P), air tank, and wheel steel.

Structural optimization based on mixing operating conditions, using CAE to optimize the structure of components such as the engine, suspension bracket, and frame, improves material utilization.

More Durable

The tank body is constructed from the latest generation of special high-strength, wear-resistant steel used in truck mixers. Impact-prone areas such as the inlet/outlet hopper and chute are constructed with a three-layer wear-resistant material. The blades are constructed from high-strength, wear-resistant steel with wear strips, resulting in over twice the strength and wear resistance of conventional materials, extending the life of the superstructure.

Utilizing large blades and a multi-phase, three-dimensional mixing mode, the superstructure has a wider slump range and complies with the characteristics of Chinese concrete, resulting in more uniform mixing, faster loading and unloading speeds, and lower residue rates.

▐ Smarter

Constant tank speed control, centralized vehicle lubrication, electrically retractable and rotating main trough, and electric loading and unloading controls provide intelligent and convenient operation for concrete mixer trucks.

Real-time monitoring of vehicle operating status, feedback to the intelligent terminal, and real-time push of vehicle usage and maintenance information to customers, providing accurate and timely after-sales service.

The intelligent operation and management system for concrete mixer trucks features intelligent weighing, location monitoring, trajectory playback, and cloud-based mobile viewing, enabling vehicle process monitoring and intelligent transportation management.

Ⅳ: Longer Range, Higher Profits, Lower Management, and Longer Service Life

The wave of energy transformation is sweeping the entire construction transportation industry. Against the backdrop of "carbon neutrality," "dual carbon goals," and "low-carbon urban construction," concrete transportation is no longer just a competition of horsepower and attendance—it's about being more energy-efficient, more intelligent, and more sustainable.

Looking to the future and standing ahead of the times, from the "fuel-powered era" to the "new energy era," CIMC Vehicles and FAW Jiefang's new energy concrete mixer trucks have proven through countless projects that reliability is the greatest value and stability is the best cost control.