Twenty years have passed in the blink of an eye. The concept that "lucid waters and lush mountains are invaluable assets" has taken deep root in people's hearts, transforming from a grand blueprint into a vibrant practice across the country. As green development becomes a consensus of the times, how should manufacturing enterprises respond? Today, let us temporarily leave behind famous mountains and rivers and step into CIMC Mixing, witnessing the "lucid waters and lush mountains" embodied in its mixer trucks amidst the light and shadow of late autumn and early winter.

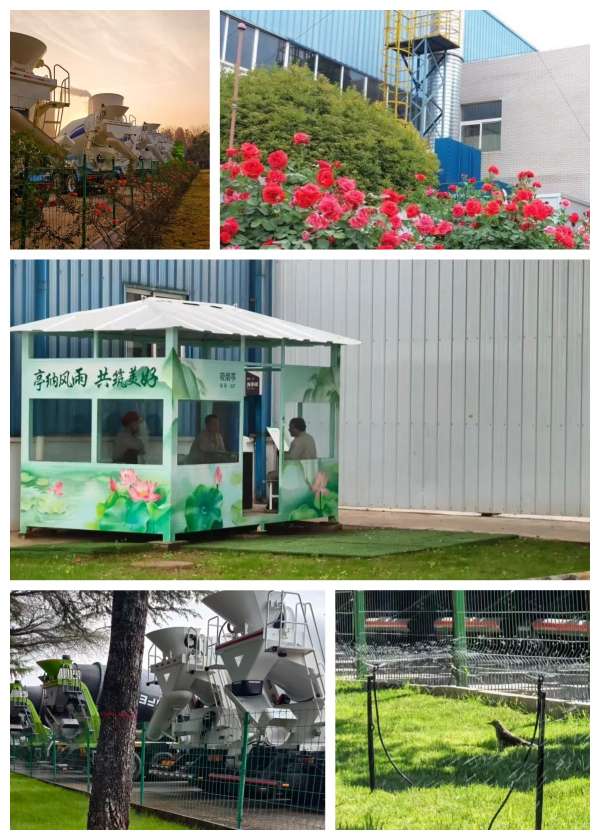

The late autumn sunlight sweeps across the blue workshop, casting sparse tree shadows on the lawn. The early winter lawn still retains some of its green, the white tanks reflecting the flowing clouds, creating a picturesque scene with the evergreen holly. The lotus pond mural in the smoking pavilion exudes the warmth of ecological manufacturing. Every interplay of light and shadow is a spatial dialogue between industry and nature.

Every blade of grass and every tree in the factory area is not just scenery, but also a symbol of CIMC Mixing's original aspiration of "manufacturing and nature going hand in hand." As a professional mixer truck manufacturer, CIMC Mixing firmly believes that heavy industry manufacturing is by no means the "opposite" to ecological protection, but rather the "main battlefield" for practicing green development.

"Made in China 2025" clearly states the need to "focus on three major directions: green upgrading of the manufacturing industry, intelligent manufacturing, and innovation in high-end equipment, and comprehensively promote the implementation of the manufacturing power strategy." CIMC Mixing actively responds to the national call, embarking on an upgrade path for intelligent manufacturing within its high-end manufacturing system, codenamed "Project Tianqi."

Laser-guided material cutting ensures precision and environmental protection; intelligent welding achieves dust removal standards; automatic powder coating results in zero VOC emissions; and intelligent assembly provides real-time monitoring—four intelligent processes that forge green and efficient production.

Green manufacturing is also hidden in the details: lightweight tanks and a low center of gravity layout reduce raw material costs while improving driving stability and energy efficiency; material selection and anti-corrosion treatment extend service life and reduce scrap rates. Strict process and quality control reduce rework rates and waste, making production itself more "economical"; regular maintenance and remote diagnostics create a long-term green usage loop.

A tree or a green belt in the factory area may not immediately change the city's ecology, but it symbolizes a choice: manufacturing and nature can coexist. Autumn may end, but the pursuit of green development will never cease.

We invite you to visit our factory and witness firsthand how "green mountains and clear waters" are realized on the production line, in the welds, and in every quality inspection. Transforming ecological requirements into a conscious manufacturing practice—this is the best response to the challenges of our time!