Whether it is a concrete mixer or a septic tank truck after a period of use, the body and the mixing tank will produce dirt, which will affect the appearance, increase the quality of the vehicle, and reduce the available volume. The following tanker sales manufacturers will take the concrete mixer truck as an example to introduce the cleaning steps and engine cleaning precautions in detail for you.

When the concrete mixer truck is transported, the concrete will solidify into a hard block in a short time. This hard block will be corrosive to steel and paint. After each use of the concrete mixing tank, it will be adhered to the concrete mixing tank and the inlet and outlet. Concrete is a daily work that must be done as follows:

1. Rinse the feed port with water before each filling to keep the feed port moist during filling;

2. Fill the washing water tank that is included with the vehicle with water at the same time as loading;

3. Rinse the feed port after charging, and wash the residual concrete near the feed port;

4. After unloading at the construction site, rinse the discharge trough, and then add 30-40L of cleaning water to the concrete storage tank to keep the concrete storage tank rotating slowly during the return journey of the vehicle;

5. Remember to let go of the sewage in the concrete storage tank before loading the next time;

6. Thoroughly clean the concrete storage tank and the inlet and outlet around the work every day to ensure that no cement and concrete agglomerates.

Step 1: First, the mixer car appliance is covered with a plastic film, and then covered with a semi-wet towel on the upper side of the film to prevent the high-pressure water from rushing into the distributor, making the mixer difficult to start.

Step 2: Use the high-pressure water gun to flush the dirt on the engine interior and the exterior of the mixer engine from the top to the bottom of the mixer engine.

Step 3: Spray the external cleaning agent of the mixer directly on the engine and engine room of the mixer after the wetting. After three minutes, use the fiber brush to clean all the parts that can be touched in the engine room.

Step 4: Quickly flush the scrubbed dirt with a high-pressure water gun.

Step 5: Then spray the external cleaning agent of the mixer engine on the surface of the engine. The operation steps are the same as above, and the machine is cleaned until the exterior of the mixer is cleaned.

Step 6: After the cleaned mixer truck is dried with a semi-wet towel, use a vacuum suction dryer to dry the area where the hand is not easily accessible, and then air dry.

Step 7: Gloss the plastic rubber parts on the inside of the engine with a plastic rubber protector, and then coat the metal parts.

Step 8: After the maintenance of the mixer truck engine and the engine interior side, clean the non-woven polishing towel for inspection.

The cleaning of the tail of the concrete mixer truck is divided into two steps, one is cleaning at the time of receiving the material, and the other is cleaning after discharging.

1. Cleaning of concrete mixer truck when receiving materials:

The stain is concentrated on the bottom of the mixer at the bottom of the mixing station: the process is in the process of receiving the bottom of the concrete mixing station. The whole set of equipment can rely on the mixing station as the skeleton. The placement height of the spraying device is slightly higher than that of the mixing hopper. Only in this way can the stains be concentrated from the upper part.

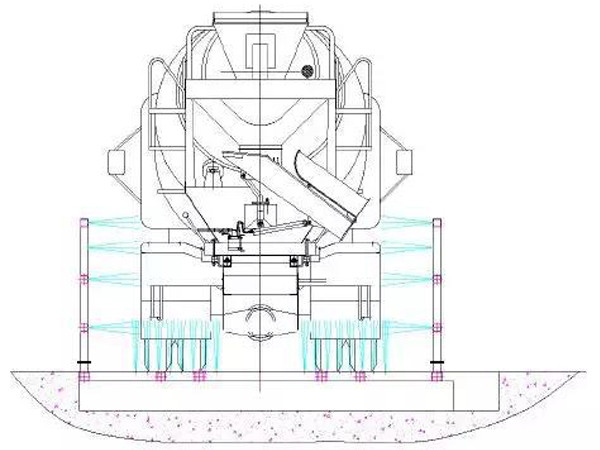

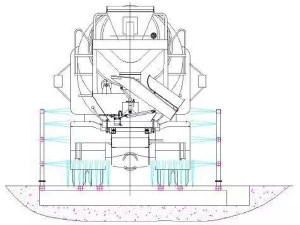

The stain cleaning method is mainly carried out by high-pressure water spraying method. Spraying pipes are arranged in the four directions of the top, the two sides and the rear part of the mixer truck, and the spray tails are respectively sprayed on the tail of the mixer to realize the stain cleaning of the concrete in all directions.

When the mixer enters the mixing station and aligns with the position of the receiving port, the spraying device first sprays the mixer car to form a water film on the surface of the mixer truck, which can further slow down the concrete solidification bonding process of splashing overflow. Carrying out the feeding operation, at this stage is the main process of concrete stain erosion to agitate the car body. The spraying device periodically sprays the tail of the mixing car to quickly remove the new sticky concrete stains and avoid the adhesion of the stains. During the spraying process, it should be noted that due to the control requirements of the concrete composition, no more sprayed clear water is allowed to enter the inner surface of the hopper, but the inner surface of the mixer hopper is often adhered with a layer of concrete residue, which can be used. The water curtain quickly and comprehensively sprays the inner surface of the mixing hopper to realize the cleaning of the inner surface.

Schematic diagram of concrete mixer tail cleaning

2. Cleaning of concrete mixer truck after unloading:

When the construction site is unloading, the stains are concentrated in the lower part of the tail of the mixer:

Since the construction process is at the construction site, the actual conditions of each construction site are not the same, and often a plurality of construction users are also supplied at the same time. For concrete production and supply enterprises, it is difficult to control the cleaning equipment of the mixer truck at the construction site. Some construction sites may not be able to guarantee even the cleaning water, which restricts the realization of the stain cleaning effect at the bottom of the mixer truck.

At present, only the water tank of the water tank of the mixer truck can be used to manually wash the discharge of the discharge port through the pipeline, thereby slowing down the dripping of the stain of the discharge tank during transportation, and the spattered stain is often in the area due to the large area. The construction site could not be processed.

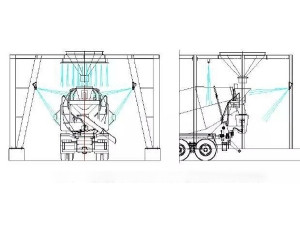

For the cleaning of the mixer truck on the construction site, the concrete production enterprise can only perform the car wash operation on the outer surface of the chassis of the car body after the mixer returns to the mixing station, and configure the bottom washing platform of the car body. The main body of the flushing platform is “ The U" structure is sprayed and washed from the lower and the three sides of the machine to the vehicle body. The device is generally placed near the entrance of the mixing station, so as to ensure that the concrete body is adhered to the shortest time for treatment. In this way, the stains at the production site can be directly cleaned. The device can not only clean the stains at the bottom of the mixer, but also transport various vehicles (including cars) to the chassis, wheels and the lower part of the car body and dust.

With the increasingly strict domestic environmental protection requirements, not only the mixer trucks are required to be cleaned at the mixing station, but also the construction units are required to enter and exit the vehicle to ensure cleaning. The construction enterprises often arrange such vehicle bottom cleaning mechanisms at the construction site. The cleaning of the stains on the bottom of the vehicle is greatly improved. Under the joint efforts of the concrete production enterprise and the concrete use enterprise, it is inevitable that the stains generated by the concrete feeding and discharging sections can be thoroughly cleaned, and the mixer is cleaned and cleaned.

Schematic diagram of bottom cleaning after unloading of mixer truck

1. First remove dirt such as dirt or dust that can be removed with water. Be sure to cover the parts before sprinkling.

2. Engine-specific cleaners should not be used on baking varnishes.

3. the most powerful dirt, you can use a foam engine-specific cleaner to deal with.

4. The aluminum tank treated water tank cover and exhaust pipe should be cleaned with a special cleaning agent.

5. Do not use powerful detergents and try household detergents.

6. The dirt solidified by high temperature is the dirt that is unique to the engine room. It is effective to use a special detergent. Concrete mixer trucks are not generally susceptible to stains, including cement, dust, mud, paint, and the like. These stains on the mixer often form dirt on the license plate, and the wipes cannot be wiped off.

If the vehicle annual inspection license is not clearly visible, it is necessary to re-exchange the license. It’s cumbersome and troublesome, and I have to pay. Usually, the concrete mixer truck is basically cleaned after each trip, and the stain on the license plate can not be cleaned for a long time, and it will become more and more dirty.

Concrete mixer maintenance knowledge

How is the cement tanker working and unloading and the structural principle?

Address:Zhangheng Street corner Guanlin Road, Science and Technology Park, Luolong District, Luoyang City, Henan Province

E-mail:shiyk@lingyu.com

Phone:0086-379-65937678